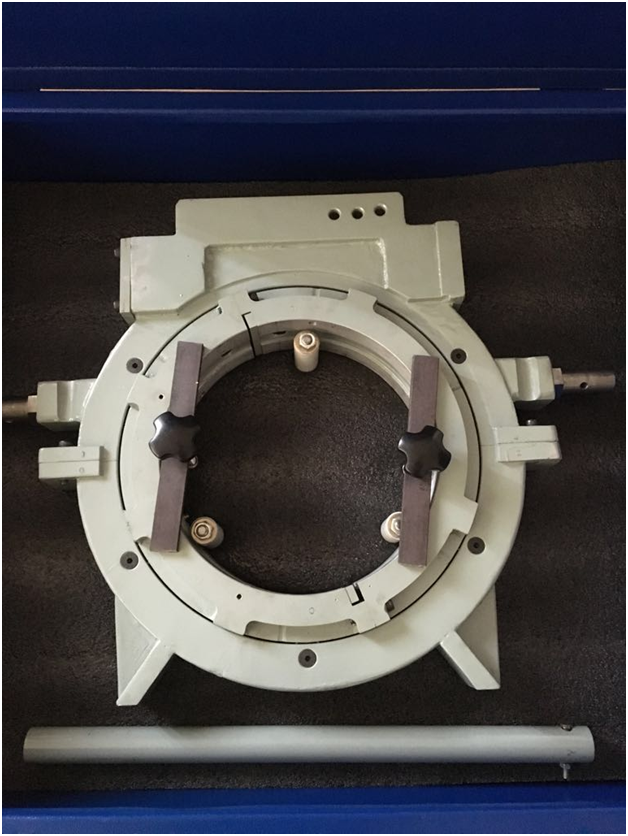

RA Power Solutions manufactures crankshaft grinding machines ranging from 60 mm to 700 mm in diameter. We designed the crankshaft grinding machine in technical collaboration with a leading Italian company. The Crankshaft Grinding machine is portable, lightweight, and easy to operate. The technicians can transport the machine as luggage to any part of the world.

Conventional Bench-Type Crankshaft Grinding Machines Are Outdated For the Repair of Crankshafts

In olden times, in case of any breakdown in the crankshaft, the only option was to remove it from the ancient block and send it to the designated workshop, duly packed for repair. The whole process was not only time-consuming, but also very expensive for the complete engine to be disassembled. Additionally, the crankshaft could potentially sustain damage during transportation.

Primary Features of the Innovative Onsite Crankshaft Grinding and Polishing Machine

(i) The State-of-art onsite grinding machine replaced the obsolete heavy-duty bench-type crankshaft grinding machine.

(ii) The onsite crankshaft honing and polishing machine is portable, enabling operators to conveniently transport it aboard a vessel, to a power plant, or to any installation globally.

(iii) Simple to operate and straightforward to maintain.

(iv) We developed the onsite crankshaft grinding and polishing machine to ensure precise control of tolerances in taper, ovality, surface finish, runout, and other parameters. All adhere to the manufacturer’s specifications.

(v) Our workshop offers complimentary onsite training.

Assessment of Quality and Reliability in Insitu Crankshaft Grinding Equipment

RA Power Solutions is an ISO-certified organisation, dedicated to maintaining rigorous quality control standards throughout the manufacturing process.

The primary structural component of our insitu crankshaft grinding machine is manufactured from high-grade titanium steel, a material selected for its inherent vibration-dampening properties. This guarantees the seamless and accurate honing and polishing of crankshafts, even during vessel operation. We rigorously inspect each component and continuously refine its metallurgical characteristics using field-testing and performance data from operational environments.

Our in situ crankshaft grinding devices are available at competitive prices, rendering them accessible to shipping companies, power generation facilities, and engine repair establishments. Typically, it takes two to three assignments to recover the initial investment. Eliminate dependence on expensive European services; instead, procure your own equipment and assume complete responsibility for crankshaft maintenance, thereby realizing savings in both time and financial resources.

Introduction of the Crankshaft Grinding Machine by R A Power Solutions:

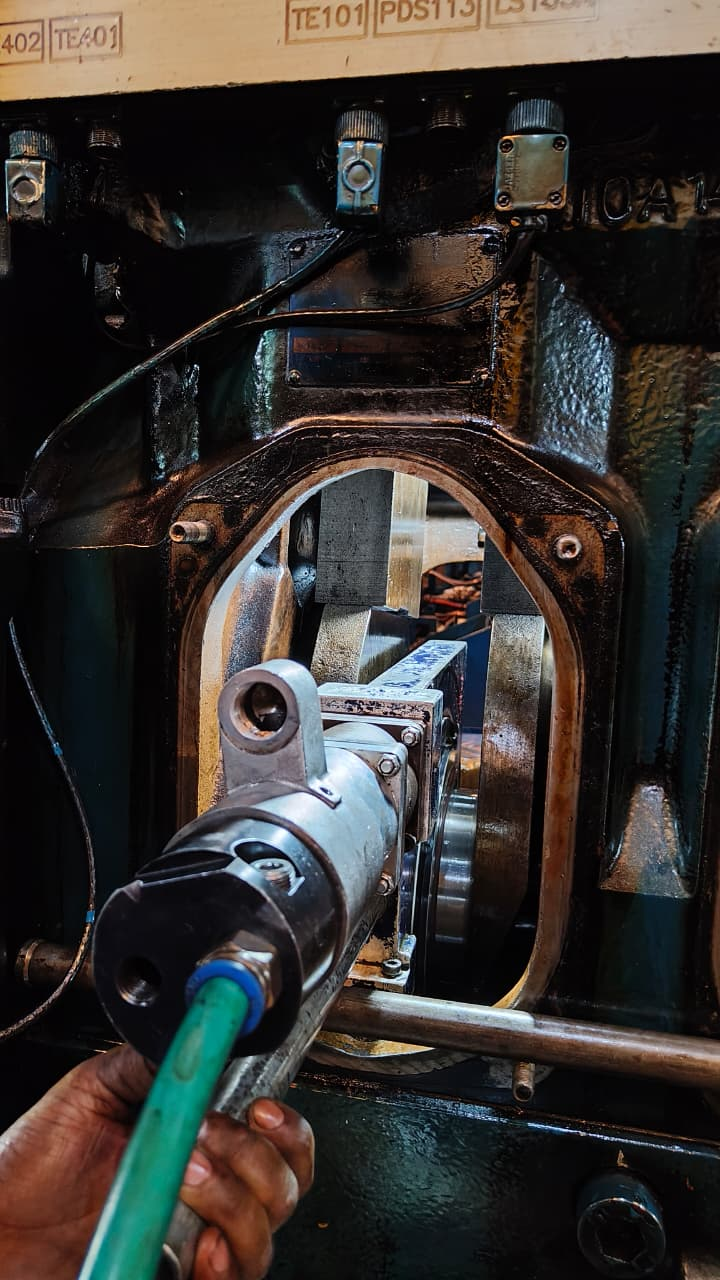

RA Power Solutions has revolutionised crankshaft repair with its onsite grinding machine. It can grind crankshafts without removing them from the block. Technicians travel worldwide with this portable machine and perform repairs directly onsite.

R A Power Solutions manufactures crankshaft grinding machines up to a diameter of 700 mm and has exported more than 88 machines all over the world. We offer free onsite training for operating and maintaining the grinding machine. You may participate in the training at our training facility near New Delhi or arrange for our team to conduct the session at your location.

Engine repair companies, shipping companies, and high-capacity power plants widely use our crankshaft grinding machines for efficient and precise engine maintenance. We sold more than a thousand onsite crankpin and main journal grinding machines worldwide. All the machines are performing satisfactorily. References can be provided upon request.

We are executing crankshaft grinding repair services in Bahrain, Kuwait, Oman, Qatar, Saudi Arabia, United Arab Emirates, Vietnam, UK, USA and other countries.

For more information on portable crankshaft grinding machines, crankshaft polishing crankpin machines, onsite grinding of crankshafts, and main journal grinding equipment, please email us at rajshahani@rapowersolutions.com, or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.