The process of repairing a crankshaft used to be very complicated and stressful. To repair a damaged crankshaft, one had to dismantle the engine, pack the parts like fragile glassware, and ship them off to a workshop. It was expensive, slow, and honestly… a huge headache. However, the onsite crankshaft grinding machine arrived and flipped the script.

Features of the Crankshaft Grinding Machine

1. Portable Design:

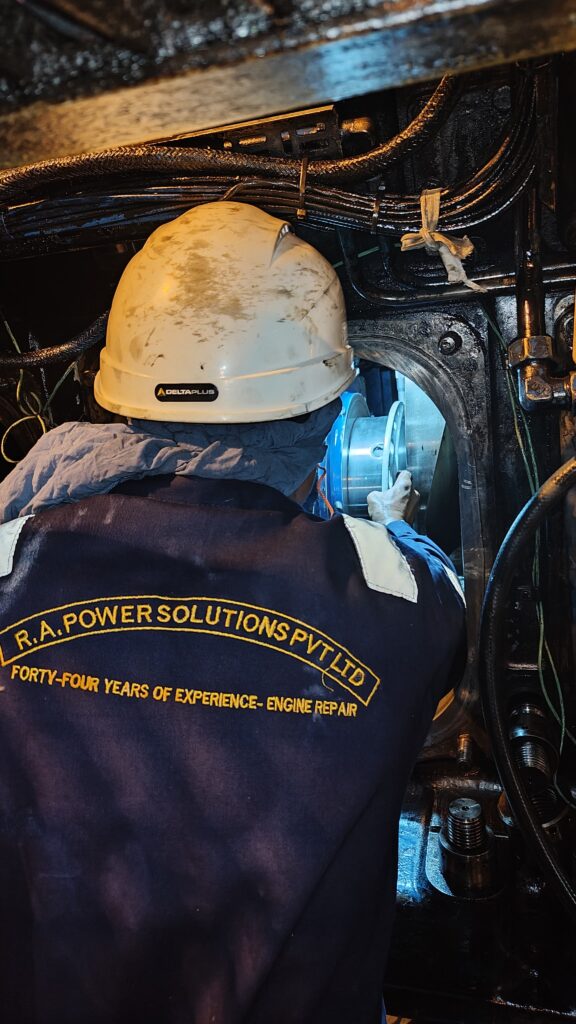

- Crankshaft grinding machine specifically developed for onsite crank pin grinding and polishing in confined spaces.

- Eliminates the need to remove the crankshaft from the entablature, minimizing downtime.

- Lightweight and Ergonomic:

- We continuously optimize component weight to ensure easy handling and global transportation.

- Designed for operator comfort and convenience during repair operations.

2. High-Quality Construction:

- We build the main body with high-grade titanium alloy for unmatched strength and vibration control.

3. Precision and Performance:

- Capable of maintaining close tolerances of 0.02 mm.

- The crankshaft grinding machine is used even while the vessel is sailing, ensuring uninterrupted operations.

4. Single-Setting Operation:

- Both crankpin and main journal grinding and polishing can be performed in one setup.

- Eliminates the need for multiple adjustments during operation.

5. Versatile Functionality:

- Suitable for honing and polishing when damage is minor, without reducing the crankshaft diameter.

- Effectively removes surface line marks, pitting, and rust to improve surface finish.

6. Complete Supply Package:

- Delivered with all necessary consumables, sufficient to grind or polish one complete crankshaft.

7. Training and Support:

- A senior technician is deputed to the client’s site for comprehensive training.

- Training covers equipment operation, handling, and maintenance.

The Crankshaft Grinding Machine isn’t just portable—it’s precise.

We’re talking accuracy within 10 microns (that’s micrometer-level precision), with surface finishing that complies with international quality standards. It’s lightweight, simple to carry, and super user-friendly.

Technicians don’t need to be hardcore specialists. With a quick 1-week training (yes, literally just a week), they’re able to grind and polish crankshafts like pros.

In Situ Crankshaft Grinding Machine | R A Power Solutions

RA Power Solutions has already delivered 1500+ crankshaft grinding and polishing machines worldwide, powering industries like:

- Marine & shipping fleets

- Repair & maintenance workshops

- Heavy engineering plants

These machines aren’t just tools—they’re profit boosters.

Less downtime means more productivity, which saves more money.

For any information, please email us at rajshahani@rapowersolutions.com, info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.