When a crankshaft gets damaged, most companies panic and start dismantling the whole engine. That’s expensive, slow, and honestly… outdated. RA Power Solutions saw the chaos and said, “Why not grind the crankshaft right where it is located?” That is precisely the reason RA Power Solutions revolutionized the industry with in situ crankshaft grinding and refining, which involves repairing the crankshaft without disassembling the entire engine.

Certainly, you have read that correctly. No disassembly. There is no shipping available. There is no need to wait for weeks.

What distinguishes RA Power Solutions?

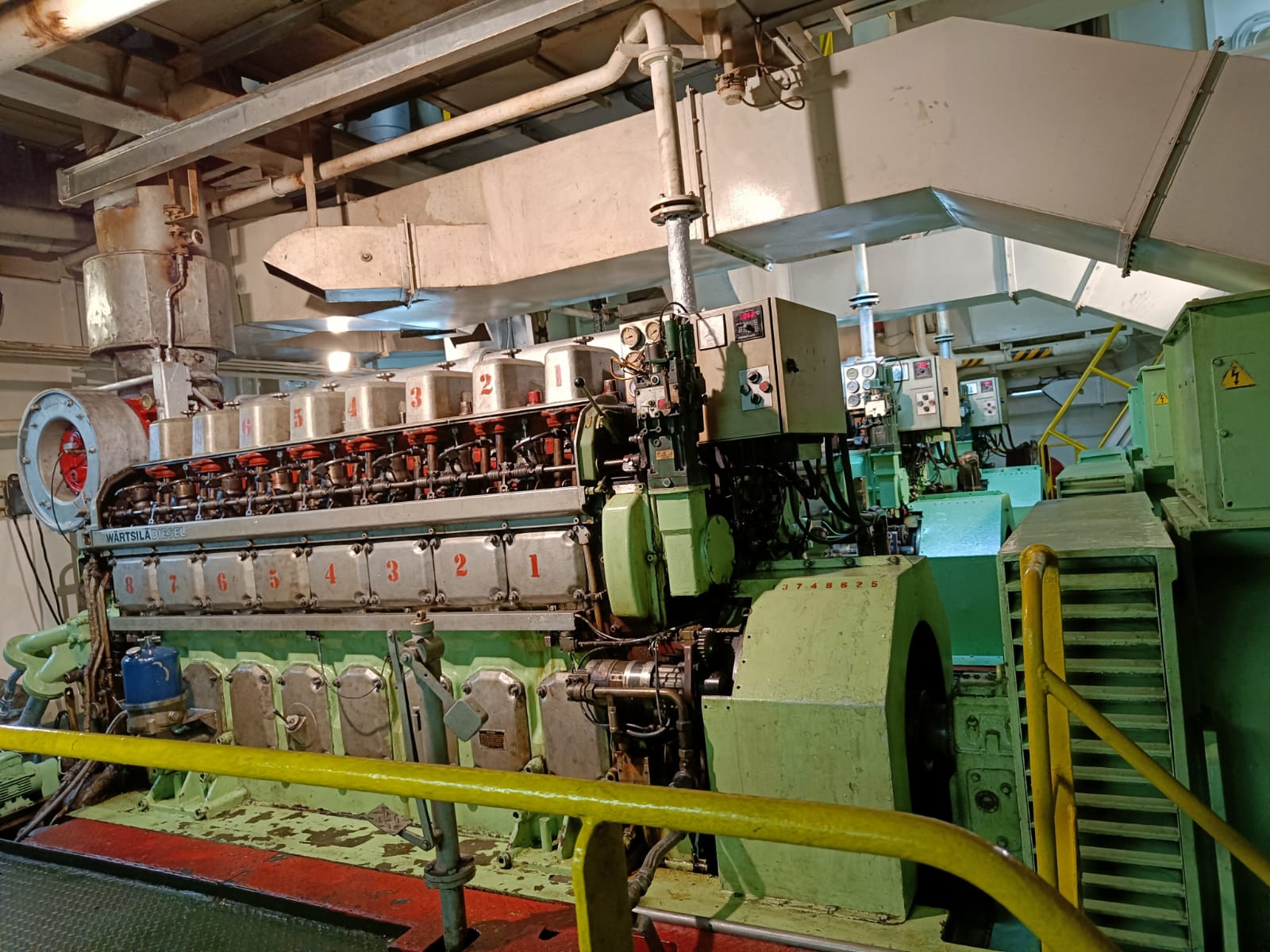

They possess a fleet of in situ crankshaft grinding machines that are portable, compact, and designed to perform precise repairs at your location. This service is available whether you are on a marine vessel in the middle of the ocean or at a power plant that cannot shut down.

These devices accommodate crankshaft diameters ranging from 35 mm to 700 mm. That essentially encompasses the majority of auxiliary and main engines utilized in heavy industry, mining, power plants, and shipping.

Why In Situ Crankshaft Grinding Is a Smart Choice

-

No disassembly is required.

- Beware of the antiquated approach that necessitates the complete removal of the crankshaft and its transportation to a workshop.

- The portable machine penetrates the engine block through the inspection window and completes the task immediately.

-

Significant time saving

- Repairs that have historically required weeks?

- The team can resolve specific crankshaft issues in as little as 24 hours with RA Power Solutions—prompt turnaround results in minimal downtime.

-

Extremely cost-effective

- There are no logistics expenses.

- There is no charge for reinstallation.

- No production revenue was lost while the crankshaft was awaiting its return from the workshop.

- A rapid resolution results in a reduction in expenditures.

-

Precision equivalent to that of the original equipment

- The crankpin is precisely restored to the OEM tolerance through the crankshaft grinding and polishing procedure.

- The surface quality has been enhanced to 0.2 micron Ra, which translates to smooth AF.

- It is also possible to polish and refine.

- Polishing/honing can be performed without the need for full grinding if the crankpin has minor damage or if a surface finish enhancement is required.

Real Results. Real Experience.

This is not a novel concept for RA Power Solutions. For more than 45 years, they have been servicing engines on a global scale, including those in factories, power plants, and ships.

They did not merely perfect the process; they also constructed their own onsite crankshaft milling machine and have already sold over 70 units worldwide.

The most intriguing aspect is that they provide complementary training to the client’s technicians during the project, ensuring that your team is fully informed about the situation.

Why the industry relies on RA Power Solutions

Over 45 years of experience in crankshaft repair

• Portable crankshaft grinding machines for 35 mm to 700 mm shafts

• Precision repair without engine disassembly

• Fast turnaround and global reach

• Technicians trained onsite

Are you prepared to restore your crankshaft without interrupting your operations?

Call/WhatsApp: +91 9582647131, +91 9810012383.

Email: rajshahani@rapowersolutions.com and info@rapowersolutions.com

Refrain from squandering time on obsolete crankshaft repairs. Ensure that your plant remains operational. Continue earning.

Our organization, RA Power Solutions, is committed to your support.