A leading power plant based in Madagascar, East Africa, reported a failure of the crankshaft of a Wartsila 9L20 diesel generating set. They have multiple Wartsila DG sets of different models. They also operate Caterpillar engines.

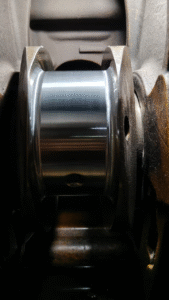

Power plant officials were advised to open all the connecting rods and visually inspect the crankpins of the Wartsila 9L20. Damage to crankpin number #09 was reported. On going through the photographs of the damaged crankpin, the radius fillet on both sides of crankpin number #09 was observed to be damaged.

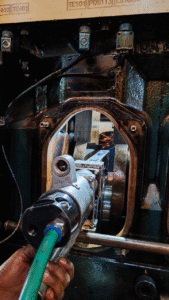

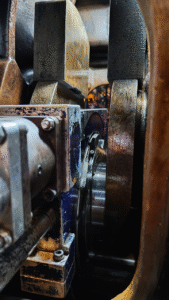

RA Power Solutions‘ two (2) technicians, along with an onsite crankshaft grinding machine, were deputed from our plant in New Delhi. The details of the engine and crankshaft are as follows:

| S. No. | Crankpin Details | |

| 1 | Engine Make | Wartsila |

| 2 | Engine Model | W9L20 |

| 3 | Crankpin Diameter Standard | 180.00 MM |

| 4 | Crankpin Bearing Width | 70.00 MM |

| 5 | Grinding of Crankpin Number | #09 |

| 6 | Place of Execution of Grinding of Crankpin | Diego Site, Madagascar, East Africa |

| 7 | Name of Shipping Company | Reputed Company from Madagascar, East Africa |

| 8 | Date Of Execution | 28th September to 2nd October 2025 |

Action Taken by RA Power Solutions to Repair the Crankshaft of Wartsila 9L20 in Madagascar, East Africa

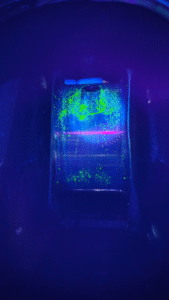

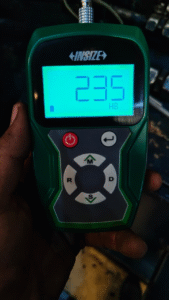

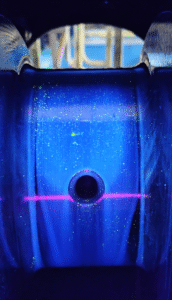

i) RA Power technicians followed a standard inspection protocol, during which the damaged crankpin number 9 was subjected to a dimensional check, crack detection by MPI, hardness check, etc. A pre-inspection report was prepared.

ii) On inspection of crankpin #09, excessive ovality of 0.41 mm was observed against the specified limit of 0.03 mm. The dimensional report is pasted below. Technicians also observed bearing line marks on the crankpin.

| SIZE OF CR PINS BEFORE REPAIR | |||||||||

| A | Aa | C | Cc | B | Bb | Min | STD | Ovality | |

| CR-1 | |||||||||

| CR-2 | |||||||||

| CR-3 | |||||||||

| CR-4 | |||||||||

| CR-5 | |||||||||

| CR-6 | |||||||||

| CR-7 | |||||||||

| CR-8 | |||||||||

| CR-9 | 179.93 | 179.62 | 179.90 | 179.78 | 179.78 | 179.59 | 179.59 | 180.00 | 0.41 MM |

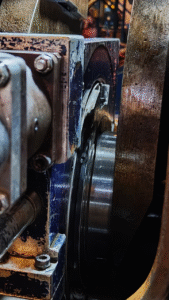

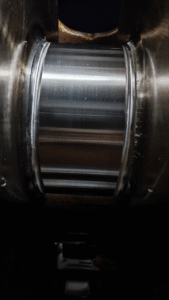

iii) RA Power Solutions carried out the repair by undersizing crankpin #09 of the Wartsila 9L20 by 1.00 mm, as the power plant had a 1.00 mm undersized bearing available. The engine was successfully commissioned in the presence of our technicians.

iv) The onsite crankshaft grinding machine, developed and manufactured by RA Power Solutions, is of the latest design and maintains a tolerance within 0.02 mm (20 microns) after grinding. The surface finish achieved is of a very high standard—15 RA value or less—which is highly recommended for ensuring the long life of bearings and crankshafts.

RA Power Solutions offers onsite crankshaft grinding and repair services under a wide range of conditions, whether on a ship at sea or at a power plant/cement plant in a remote location. All crankshaft grinding services provided by RA Power are guaranteed to ensure the satisfactory performance of the crankshaft and diesel engine after repairs.

RA Power Solutions is a well-known company that provides crankshaft repair, machining, and engine overhaul services on site to the marine, industrial, and power-generating sectors all over the world. The company has been in business for more than 45 years and has completed projects in Asia, Africa, Europe, the Middle East, and South America, bringing precision-engineered solutions right to clients’ premises. RA Power Solutions has powerful portable machining machines and a team of highly qualified experts. This means they can respond quickly, make repairs that are cost-effective, and do work that is as accurate as the original equipment manufacturer (OEM) anywhere in the world.

For more information on onsite crankshaft repair, grinding of crankshaft, and crankshaft polishing, please email us at rajshahani@rapowersolutions.com, or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.