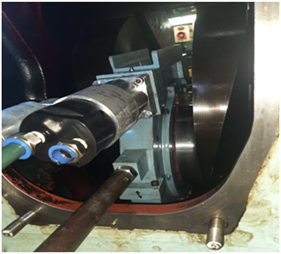

RA Power Solutions, with 45 years of experience, has introduced a mobile service for machining of crankshafts and cylindrical shafts onsite. The failure of a compressor, pump, engine, or crankshaft in any reciprocating equipment can result in extremely high costs and significant downtime.

RA Power Solutions introduced mobile in situ machining services to cut repair costs and save time by avoiding disassembly, removal, and transport of shafts to workshops. We machine all types of cylindrical shafts and crankshafts up to 700 mm in diameter. We maintain tolerances according to the manufacturer’s requirements.

Advantages of Mobile Machining of Cylindrical Shaft and Crankshaft Onsite:

- We use advanced technology and processes for the machining of cylindrical shafts and crankshafts.

- Onsite machining equipment is portable and can be taken all over the world by our technicians.

- Customization of onsite machining tools is possible according to the specifications of the shaft and site requirements.

- Crankshaft Grinding Mobile Services machining minimizes the downtime and cost of the repairs.

- Mobile machining is of great advantage to the plants as we are available 24*7 and can fly to any part of the world on short notice.

- All our technicians experienced and trained in our in-house training school.

- We have 45 years of experience. We regularly provide mobile machining services to leading companies across the world.

- We design mobile machining equipment to undertake machining of damaged crankshafts in main and auxiliary engines installed on vessels.

- Mobile machining is also possible while sailing of the vessel.

For more information regarding crankshaft machining, cylindrical shaft machining, and Crankshaft Grinding Mobile Services, please contact us at rajshahani@rapowersolutions.com or info@rapowersolutions.com or call us at +91 9582647131 or +91 9810012383.